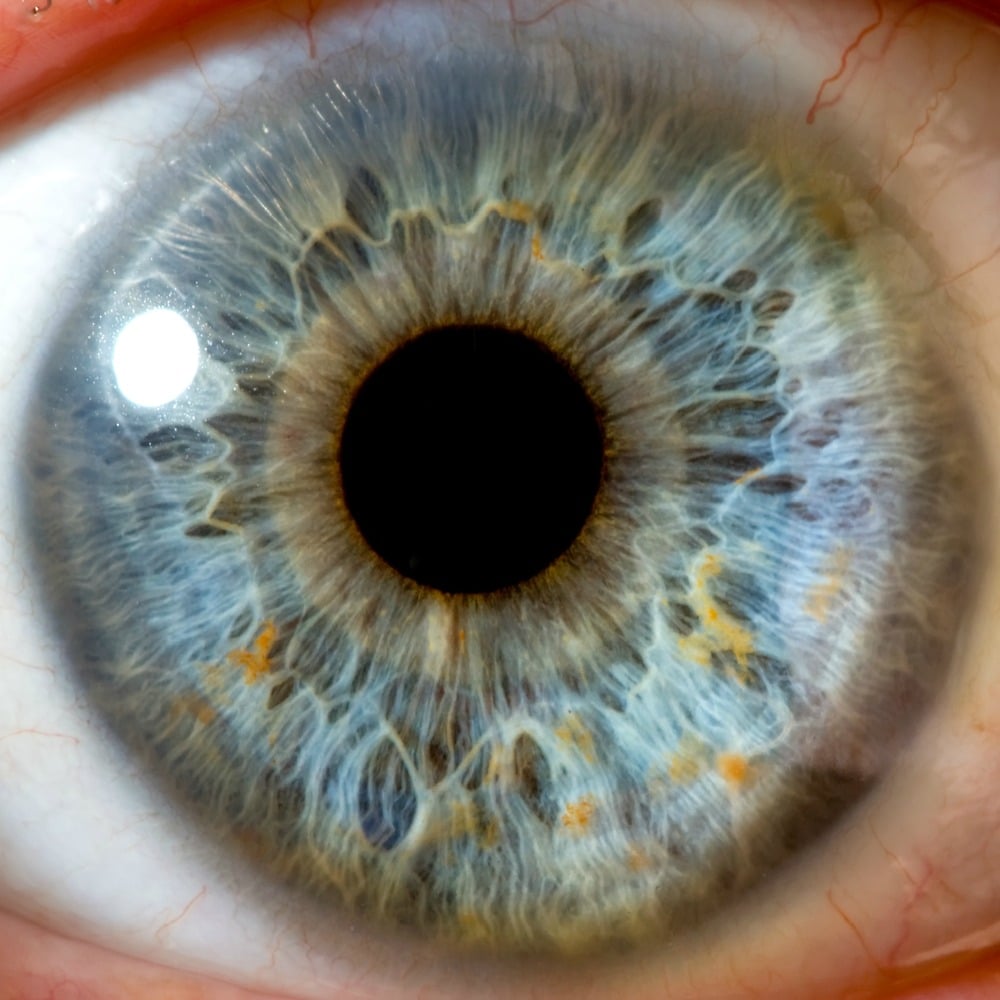

Researchers developed an adaptive metalen made of silicon which is essentially a flat electronically controlled artificial eye that simultaneously controls 3 major contributors to blurry images such as image shift, focus, and astigmatism, which can change in real time just like the human eye. The lens and muscle are only 30 microns thick in size together.

To build the artificial eye researchers had to adapt and improve metalens that previously were the size of a piece of glitter. Nanostructures of the metalens are small making the density of information in each lens being incredibly high. When the team tried to scale up the lens the file size would balloon up, development of a new algorithm was needed to address the issue to shrink file size and make the metalens compatible with the technology used to fabricate integrated circuits. Next the metalens need to be adhered to an artificial muscle without compromising the ability to focus light. Using a thin low gloss transparent dielectic elastomer to attach to the lens, which the team had to then develop a platform to use to transfer and adhere the lens to the soft surface with. The elastomer is controlled by applying voltage, position of n on the surface of the lens shift as it stretches. Tuning of the metalens is done by controlling the position of the pillars in relation to neighbors and displacement of structures. The lens is capable of simultaneously focus, image shift, and control aberrations caused by astigmatisms.

This research could unify 2 industries may be made possible in lens making and semiconductor manufacturing, the same technology used to make computer chips will be used to make the metasurface based optical components. It also demonstrates the feasibility of embedded autofocus and optical zoom for a variety of applications such as eyeglasses, cell phone cameras, and virtual reality hardware, along with future possibilities of optical microscopes which could operate electronically and correct aberrations simultaneously.