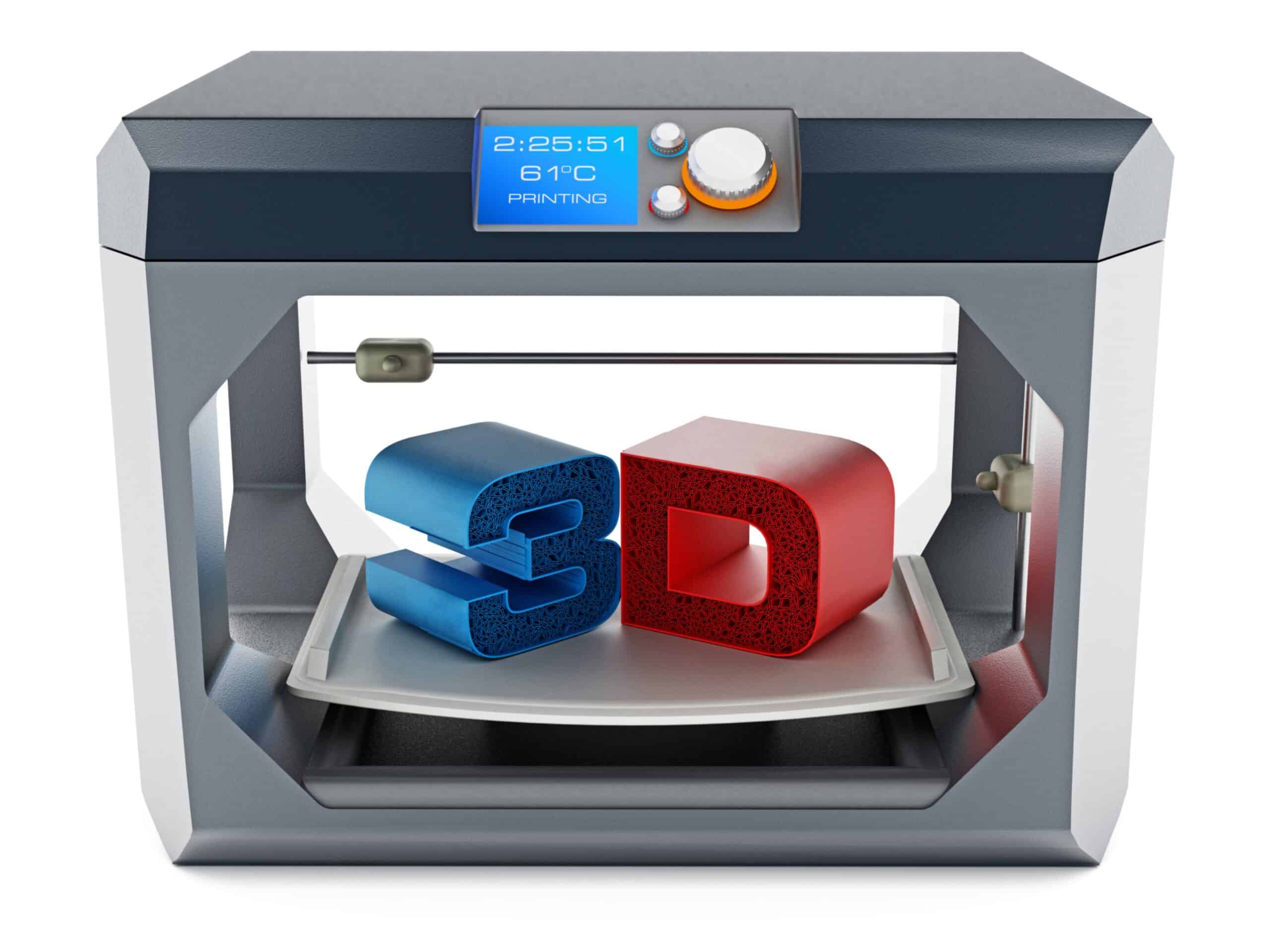

Combination of automated musculoskeletal tissue production using 3D bioprinting with new microwell plates will address specific tissue attachment requirements, the novel screening platform could represent promising new tools for possible future musculoskeletal drug discovery and development.

Tissue models are fabricated using alternating layers of bioink based photopolymerized gelatin methacryloyl materials and cell suspensions in dumbbell shape onto newly designed cell culture inserts in 24 well plates which contain two vertical posts. Based on protein expression and gene markers cells show high viability after culture printing and good texture differentiation.

Evidence of viability was demonstrated via electrical pulse stimulation to induce myofiber contractility, and calcium signalling from Fluo4 loaded cells; successful tendon muscle tendon co-culture fabrication was produced by bioprinting tenocytes around posts of the cell culture inserts and myoblasts between the posts.